Clicking on Amazon Services LLC Associates Program links on our site may earn us a commission. We provide unbiased overview of products and your support keeps us honest and objective. Thank you for helping us continue our work. Learn More →

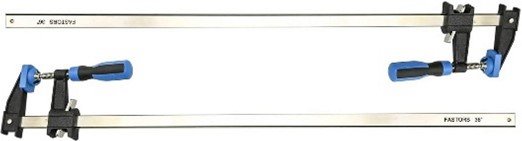

Bar clamps

top picks

a Tool for Every Job

Bar clamps are required tools in the resource of both experienced tradespersons and enthusiastic DIYers. These versatile clamps are essential for securing workpieces during various woodworking, metalworking and crafting projects providing stability and precision to achieve desired results. Their introduction marks a significant advancement in the realm of clamping technology offering a robust and efficient solution for holding materials firmly in place during intricate tasks.

For tradespersons, bar clamps represent a reliable companion in their daily endeavors. Whether constructing furniture, installing cabinetry or fabricating metal structures these clamps ensure that workpieces remain securely positioned allowing professionals to execute their craft with utmost accuracy and efficiency. The introduction of bar clamps has revolutionized the way tradespersons approach their projects enabling them to tackle complex tasks with confidence and skill.

Similarly, DIYers find bar clamps to be indispensable tools in their workshops. From building shelves to refurbishing old furniture these clamps provide the necessary stability to execute DIY projects with precision and ease. With their user-friendly design and adjustable features bar clamps enable enthusiasts to take on a wide range of tasks turning their creative visions into tangible realities. The introduction of bar clamps has democratized craftsmanship allowing DIYers to achieve professional-quality results without the need for specialized skills or equipment.

Bar clamps have had a profound impact on both tradespersons and DIY enthusiasts revolutionizing the way they approach their respective crafts. These versatile tools embody reliability, precision and efficiency allowing users to tackle projects of all scales and complexities with confidence and ease.

BUYERS GUIDE

bar clamps

Clamping Capacity:

Assess the clamping capacity required for your typical projects. Medium duty bar clamps usually have a range of capacities so choose one that accommodates the majority of your workpiece sizes.

Build Quality:

Consider bar clamps constructed from durable materials like steel or aluminum. Ensure that the clamp’s frame and bar are sturdy enough to withstand regular use without bending or warping.

Clamping Mechanism:

Evaluate the clamping mechanism for efficiency and ease of use. Look for features such as quick-release mechanisms or one-handed operation which enhance convenience during clamping and unclamping.

Throat Depth:

Consider the throat depth of the clamp which determines how far the clamp can reach into a workpiece. A deeper throat depth allows for greater versatility in clamping various shapes and sizes of materials.

Handle Design:

Examine the handle design for comfort and ergonomics especially if you anticipate using the clamps for extended periods. Cushioned or contoured handles can reduce hand fatigue and improve grip during operation.

Jaw Material:

Check the material of the clamp jaws to ensure they provide sufficient grip without damaging delicate surfaces. Soft rubber or non-marring pads on the jaws are ideal for protecting workpieces from scratches or dents.

Adjustability:

Look for adjustable features such as sliding jaws or reversible heads which enable the clamp to adapt to different project requirements. Versatile clamps offer greater flexibility and utility in various applications.

Brand Reputation and Reviews:

Research reputable brands known for producing high-quality clamps and read reviews from other users to gauge reliability, performance and durability. Customer feedback can provide valuable insights into the strengths and weaknesses of different models.

Price and Value:

Compare prices across different brands and models while considering the features and quality offered. Aim for a balance between affordability and value ensuring that you’re getting a reliable tool that meets your requirements without overspending.

Warranty and Customer Support:

Check the warranty coverage and available customer support services offered by the manufacturer. A solid warranty provides peace of mind and assurance of quality, while responsive customer support can assist with any issues or inquiries that may arise post purchase.