Clicking on Amazon Services LLC Associates Program links on our site may earn us a commission. We provide unbiased overview of products and your support keeps us honest and objective. Thank you for helping us continue our work. Learn More →

Hacksaws

top picks

What’s in the Toolbox

tool

features

options

Option 1

1 PACK (KT21018T)

(1) Hacksaw 300mm (12″)

(1) Mini Hacksaw 250mm (10”)

(1) Drywall Saw/Jab Saw

(2) 300mm (12”) Flexible Bi-metal HSS Blades

(2) 250mm (10”) Flexible Bi-metal HSS Blades

a Tool for Every Job

Hacksaws are essential hand tools highly valued by both tradespersons and DIYers for their exceptional versatility and reliability. With a fine-toothed blade held under tension within a robust frame, hacksaws are adept at cutting through a diverse range of materials including metal, plastic and wood. For tradespersons such as plumbers, electricians and metalworkers the hacksaw is an key tool. It is crucial for precision tasks like cutting pipes, metal rods and trimming screws and bolts ensuring clean and accurate cuts.

Hacksaws provide a versatile solution for a variety of home projects and repairs. Whether undertaking home improvement tasks, crafting or routine maintenance, the hacksaw’s straight forward design and user-friendly design make it an essential tool to have in the toolbox. Its compact size and manual operation allow for a hands on approach eliminating the need for complex power tools and enabling users to tackle projects with confidence and precision. The adjustable frame which can accommodate different blade lengths and types, further enhances its utility making it adaptable to a wide range of materials and cutting requirements.

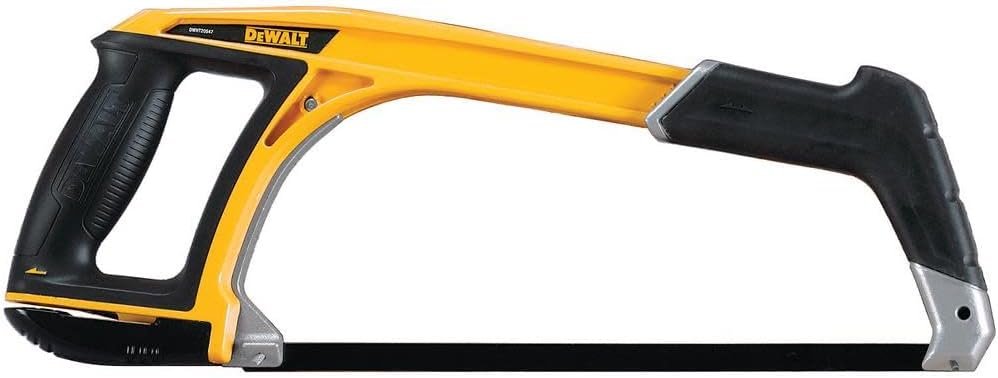

Modern hacksaws are designed with ergonomics in mind featuring comfortable handles that reduce hand fatigue and improve control during extended use. The availability of replacement blades in various tooth configurations allows for customization based on specific cutting needs enhancing the tool’s efficiency and precision.

BUYERS GUIDE

Hacksaws

Frame Construction:

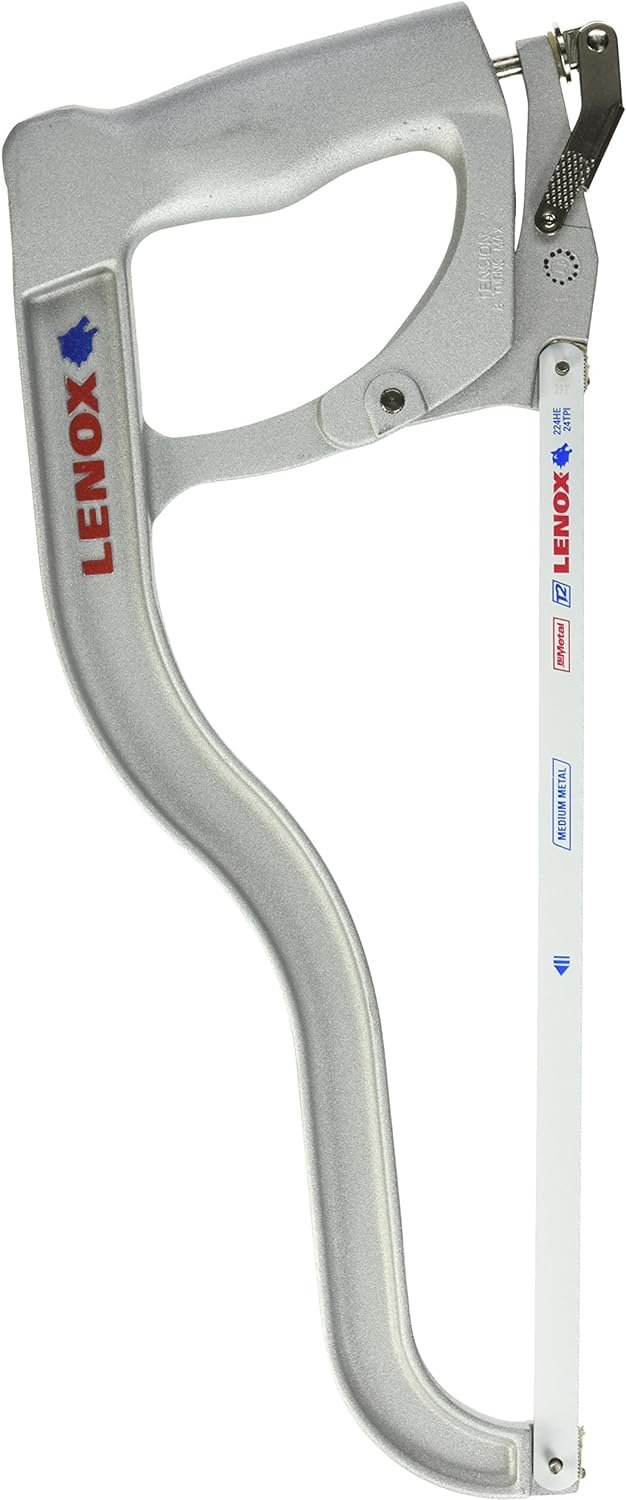

The frame of a hacksaw should be sturdy and made from high quality materials such as steel or aluminum to prevent flexing during use. A rigid frame ensures consistent blade tension resulting in cleaner cuts and a longer blade life. Adjustable frames that can accommodate different blade lengths offer added versatility.

Ergonomic Handle:

A comfortable ergonomic handle is crucial for prolonged use. Look for handles made from materials like rubber or plastic that provide a secure grip and reduce hand fatigue. A well designed handle enhances control and precision making cutting tasks easier and safer.

Blade Tensioning Mechanism:

Ensure the hacksaw has an easy to use tensioning mechanism such as a thumb screw or lever. Proper blade tension is key to achieving accurate cuts and preventing the blade from slipping or breaking. Quick release tensioning systems can simplify blade changes and adjustments enhancing overall efficiency.

Blade Length and Depth:

Standard hacksaw blades are typically 300mm (12″) long but some frames can accommodate shorter or longer blades. Consider the depth of the frame as well, deeper frames allow for greater cutting capacity which is useful for larger or thicker materials.

Versatility:

Some hacksaws come with additional features such as adjustable frames or pivoting handles, which can enhance their versatility. Interchangeable blades that can cut different materials add further value making the tool adaptable to various tasks.

Brand Reputation and Reviews:

Consider reputable brands known for their quality tools, such as Stanley, Bahco, or Lenox. Reading customer reviews can provide insights into the hacksaw’s performance, durability and any potential issues helping you make a more informed decision.

Price and Warranty:

While price is an important consideration investing in a higher quality hacksaw often results in better performance and longevity. Look for models that offer a good balance between cost and features. Additionally, a warranty from the manufacturer provides peace of mind, ensuring support if any problems arise with the tool.