Clicking on Amazon Services LLC Associates Program links on our site may earn us a commission. We provide unbiased overview of products and your support keeps us honest and objective. Thank you for helping us continue our work. Learn More →

Jack Planes

top picks

a Tool for Every Job

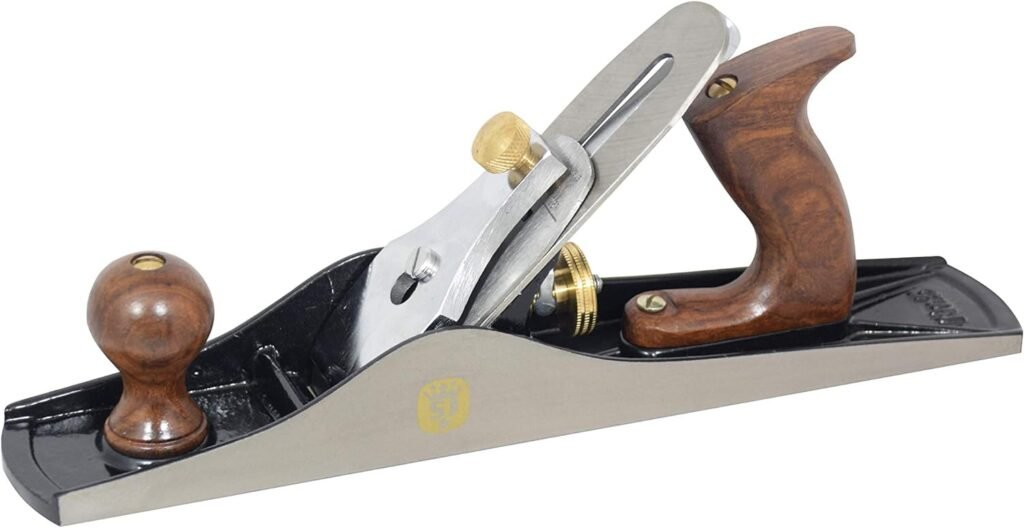

The Jack Plane stands as an iconic tool by tradespeople across generations for its required role in woodworking. Renowned for its usefulness and accuracy the Jack Plane is a cornerstone in the toolbox of carpenters, furniture makers and craftspeople. Its primary function lies in smoothing and shaping wood essential for creating precise joinery, refining surfaces to perfection and ensuring structural integrity in woodworking projects.

Carpenters rely on the Jack Plane to flatten rough timber, preparing it for construction with precision and efficiency. Furniture makers use it to craft elegant designs, smoothing surfaces to a finish that enhances both aesthetics and functionality. In the hands of skilled tradespeople the Jack Plane embodies craftsmanship and artistry, transforming raw materials into refined pieces.

Beyond its technical utility the Jack Plane symbolizes the dedication and expertise of tradespeople. It requires skillful manipulation and an understanding of wood grain and tool mechanics reflecting a deep rooted commitment to excellence in the trade. Whether in traditional workshops or modern studios the Jack Plane remains a testament to craftsmanship bridging past traditions with contemporary innovation in woodworking and design.

BUYERS GUIDE

Jack Planes

Quality of Materials and Construction:

The foundation of a reliable Jack Plane lies in its materials and construction. Look for planes crafted from high grade steel for the blade and a sturdy body made of hardwood or robust metal. This ensures durability and resilience crucial for enduring the demands of woodworking tasks while maintaining precise performance.

Blade Sharpness and Adjustability:

The blade is the heart of any plane. Seek planes equipped with sharp high-carbon steel blades that retain their edge over prolonged use. Easy to use adjustment mechanisms for blade depth and alignment are essential allowing for precise customization to achieve smooth and controlled cuts across various wood types and grain orientations.

Comfortable Ergonomics:

Ergonomics significantly impact user comfort and efficiency. Choose a Jack Plane with a well designed handle that offers a secure grip and minimizes hand fatigue during extended use. Balanced weight distribution enhances maneuverability and control facilitating effortless operation across diverse woodworking projects.

Versatility for Various Tasks:

Consider the plane’s versatility and adaptability to different woodworking tasks. Consider models that excel in both rough stock removal and fine finishing. Adjustable throat openings and versatile blade positioning systems expand functionality accommodating a wide range of woodworking requirements with ease.

Durability and Longevity:

Ensure the Jack Plane is built to last with durable materials that can withstand heavy use without compromising performance. Look for features like rust resistant coatings or treatments that enhance longevity especially if you work in environments prone to moisture or humidity.

Compatibility with Accessories:

Consider if the Jack Plane is compatible with accessories or additional blades that can expand its functionality. Some planes offer compatibility with specialized blades for specific tasks like smoothing, jointing or creating decorative profiles providing versatility in your woodworking arsenal.

Ease of Maintenance:

Choose a Jack Plane that is easy to maintain and service. Look for models with accessible blade replacement systems or user friendly maintenance procedures outlined in the manufacturer’s guidelines. This ensures you can keep your plane in optimal condition for prolonged use.