Clicking on Amazon Services LLC Associates Program links on our site may earn us a commission. We provide unbiased overview of products and your support keeps us honest and objective. Thank you for helping us continue our work. Learn More →

Locking Pliers

top picks

What’s in the Toolbox

tool

features

options

Option 1

1 PACK

(1) Fast Release Locking Plier Set (IRHT82592)

(1) 130mm (5”) Curved Jaw Locking Pliers

(1) 150mm (6”) Long Nose Locking Pliers

(1) 180mm (7”) Straight Jaw Locking Pliers

(1) 250mm (10”) Curved Jaw Locking Pliers

Option 1

1 PACK

(1) Locking Plier Set 10 Piece (1078KB)

(1) 130mm (5”) Curved Jaw Locking Pliers

(1) 150mm (6”) Straight Jaw Locking Pliers

(1) 150mm (6”) Long Nose Locking Plies

(1) 180mm (7”) Curved Jaw Locking Pliers

(1) 180mm (7”) Straight Jaw Locking Pliers

(1) 180mm (7”) C-Clamp Locking Pliers

(1) 225mm (9”) Long Nose Locking Pliers

(1) 250mm (10”) Curved Jaw Locking Pliers

(1) 250mm (10”) C-Clamp Locking Pliers

(1) 280mm (11”) Straight Jaw Locking Pliers

Option 1

1 PACK

(1) Locking Plier Set, with Wire Cutters (36)

(1) 150mm (6”) Long Nose Locking Pliers

(1) 180mm (7”) Curved Jaw Locking Pliers

a Tool for Every Job

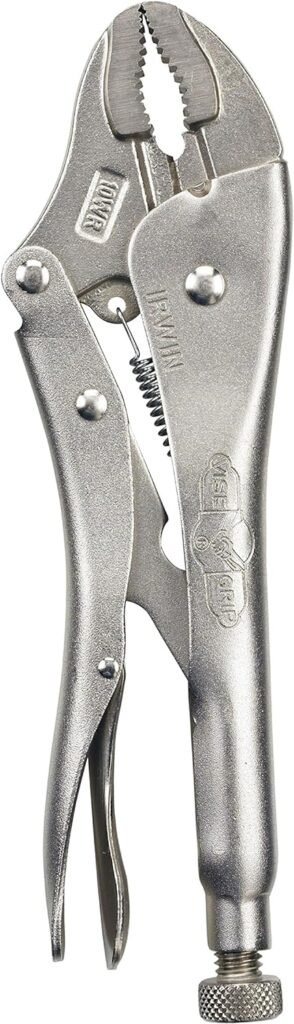

Locking pliers, often referred to as Vise Grips (a popular brand name) are essential tools in various trades and industries due to their unique design and versatile functionality. These pliers feature an adjustable locking mechanism that allows the jaws to securely grip and hold objects with a high degree of force. The ability to lock the jaws in place provides a stable and hands free grip making them invaluable for tasks that require holding, clamping or manipulating materials securely.

In the automotive trade, locking pliers are practical for tasks such as removing stripped bolts, holding parts in place for welding or clamping hoses during repairs. Their strong grip ensures that parts do not move allowing for more precise work and reducing the risk of errors or accidents. The ability to adjust the tension of the grip also means that locking pliers can be used on a wide variety of objects and materials from delicate items to heavy duty components.

In metalworking and fabrication, locking pliers serve as an extra set of hands holding pieces of metal securely while they are being cut, shaped or welded. This functionality is particularly useful in situations where traditional clamps might not fit or provide the necessary holding power. The robust design of locking pliers ensures that even under significant pressure the grip remains strong and reliable, making them a staple in workshops and on job sites.

Locking pliers also find extensive use in plumbing, electrical work and general maintenance. Plumbers use them to grip pipes and fittings securely enabling easier tightening or loosening without slipping. Electricians might use locking pliers to hold wires or components in place ensuring safety and precision in their work. For general maintenance tasks the ability to lock the pliers in place allows for a variety of applications from unscrewing tough bolts to holding objects steady for drilling or cutting.

BUYERS GUIDE

Locking Pliers

Types of Locking Pliers:

When purchasing locking pliers it’s essential to consider the different types available. Standard locking pliers are versatile and can handle various tasks but there are also specialized types such as long-nose locking pliers for reaching tight spaces, curved-jaw pliers for gripping rounded objects and C-clamp locking pliers for clamping larger surfaces. Long-nose locking pliers with their extended reach and narrow profile are ideal for precision tasks and accessing confined spaces that standard pliers cannot reach. Curved-jaw pliers offer a strong grip on round objects like pipes and bolts making them very useful for plumbing and automotive tasks. C-clamp locking pliers with their wide jaws and strong clamping force are perfect for holding large or irregularly shaped workpieces steady during welding or metalworking. Understanding the specific requirements of your tasks will help you choose the most suitable type.

Material and Durability:

The material and construction of Allen wrenches are crucial for durability and long-term performance. Look for wrenches made from high quality materials such as chrome-vanadium steel or S2 tool steel. These materials are known for their strength and resistance to wear and corrosion. A durable set of Allen wrenches will withstand frequent use and provide reliable performance over time.

Material and Build Quality:

The material and build quality of locking pliers are crucial factors to consider. High quality pliers are typically made from durable materials like chrome-vanadium steel which offers excellent strength and resistance to wear and corrosion. These materials ensure that the pliers can withstand frequent and heavy duty use without deforming or breaking. Some locking pliers feature hardened teeth that provide a more secure grip and enhanced durability. A robust build is essential for maintaining performance under stress ensuring long term reliability and efficiency. Investing in pliers made from superior materials will save you money in the long run by reducing the need for frequent replacements.

Jaw Design and Versatility:

The design of the jaws plays a significant role in the functionality of locking pliers. Consider the jaw shape and teeth configuration which should provide a secure grip on various objects. Curved jaws are ideal for gripping pipes and rounded surfaces while straight jaws offer a firm hold on flat or square objects. Versatile jaw designs can enhance the tool’s usability across different applications from gripping nuts and bolts to clamping wood or metal. Some pliers also feature serrated jaws that improve grip on slippery or smooth surfaces. Evaluating the jaw design based on the specific materials and shapes you commonly work with will ensure optimal performance and versatility in your tool collection.

Adjustability and Locking Mechanism:

The adjustability and locking mechanism of the pliers are key features to evaluate. High quality locking pliers should have a smooth and easy to operate adjustment screw that allows for precise control of the jaw opening. This adjustability is crucial for accommodating different sizes of objects and ensuring a tight grip. The locking mechanism should engage securely and release effortlessly providing reliable performance and user safety during operation. Some advanced models feature a quick release lever that simplifies the process of unlocking the jaws making the tool more convenient and efficient to use. Ensuring the locking mechanism is robust and reliable will prevent slippage and ensure a firm hold on your workpieces.

Handle Comfort and Ergonomics:

Comfort and ergonomics are important considerations especially for prolonged use. Look for locking pliers with ergonomic handles that provide a comfortable grip and reduce hand fatigue. T-handle designs and cushioned grips can enhance comfort and control allowing for more efficient and comfortable operation in various tasks. Ergonomic handles are particularly beneficial for tasks that require significant force or involve repetitive motion as they minimize strain on your hands and wrists. Non-slip surfaces and contoured grips also improve handling ensuring that you maintain a secure hold on the pliers even in challenging conditions. Investing in ergonomically designed pliers will enhance your productivity and reduce the risk of discomfort or injury during extended use.

Size and Reach:

Consider the size and reach of the locking pliers in relation to the tasks you will be performing. Smaller pliers are ideal for precision work and accessing tight spaces while larger pliers offer greater leverage and clamping force for heavy duty applications. Having a range of sizes can provide versatility and ensure you have the right tool for different situations. Long reach locking pliers can extend your access to difficult to reach areas while compact models are perfect for intricate tasks. The ability to choose the appropriate size and reach for each job enhances efficiency and ensures that you can tackle a wide variety of tasks with confidence.

Storage and Organization:

Proper storage and organization of locking pliers are important to prevent loss and damage. Look for sets that come with a storage case or pouch keeping them neatly organized and easily accessible. A well organized set can save time and frustration during use ensuring that you can quickly find the right tool when needed. Some storage solutions also offer portability making it easy to transport your pliers to different job sites. Consider the durability and design of the storage case as a sturdy and well-designed organizer can further enhance the longevity and usability of your pliers. Investing in good storage solutions will help you maintain your tools in optimal condition and extend their lifespan.

Brand Reputation and Quality:

Choosing locking pliers from reputable brands can ensure high quality and reliability. Established brands often have a track record of producing durable and well designed tools. Brands like Vise-Grip, Knipex and Craftsman are known for their high standards and innovative designs. Consider the warranty offered by the manufacturer, as a good warranty reflects confidence in the product’s durability and provides peace of mind in case of defects or issues. A strong brand reputation and comprehensive warranty support indicate a commitment to quality and customer satisfaction ensuring that your investment in locking pliers is well protected.