Clicking on Amazon Services LLC Associates Program links on our site may earn us a commission. We provide unbiased overview of products and your support keeps us honest and objective. Thank you for helping us continue our work. Learn More →

Try Squares

top picks

a Tool for Every Job

Try squares are essential tools in various trades particularly woodworking and building and construction where precision and accuracy are of greatest importance. These tools featuring an L-shaped design with a straight blade at a perfect 90-degree angle to the handle are fundamental for marking and verifying right angles. For carpenters and joiners try squares are crucial for tasks such as checking the squareness of edges, marking cut lines and ensuring that corners are accurately aligned. The ability to consistently produce straight and true angles is fundamental in these trades as it directly impacts the quality and integrity of the finished product.

Masons and tilers also rely on try squares for achieving perfect right angles in their work. When laying tiles or constructing masonry walls ensuring that each piece is square and aligned is crucial for both the structural integrity and aesthetic appeal of the project. Try squares help these tradespeople achieve precise alignment leading to more professional and reliable results. The tool’s simplicity and ease of use make it a staple in the toolbox of anyone involved in these trades from professionals to apprentices.

Beyond their practical applications try squares are also valued for their durability and reliability. Made from materials like steel, aluminum or hardened plastic, try squares are designed to endure the rigors of heavy use on job sites. Their robust construction ensures that they remain accurate and dependable providing tradespersons with a consistent reference for achieving precise angles and measurements. This reliability is critical in professional settings where the quality of work must meet high standards and any errors can lead to costly rework or safety concerns.

BUYERS GUIDE

Try Squares

Identifying Your Requirements:

When purchasing a try square, it’s crucial to first identify the specific requirements of your work. Different trades, such as carpentry, metalworking, and masonry, have varying demands. For instance, a woodworker might need a try square to ensure perfect right angles on wood joints, while a metalworker requires a more precise tool for metal fabrication tasks. Understanding the primary applications of the try square in your trade helps you select a tool that will meet your needs effectively.

Material and Construction:

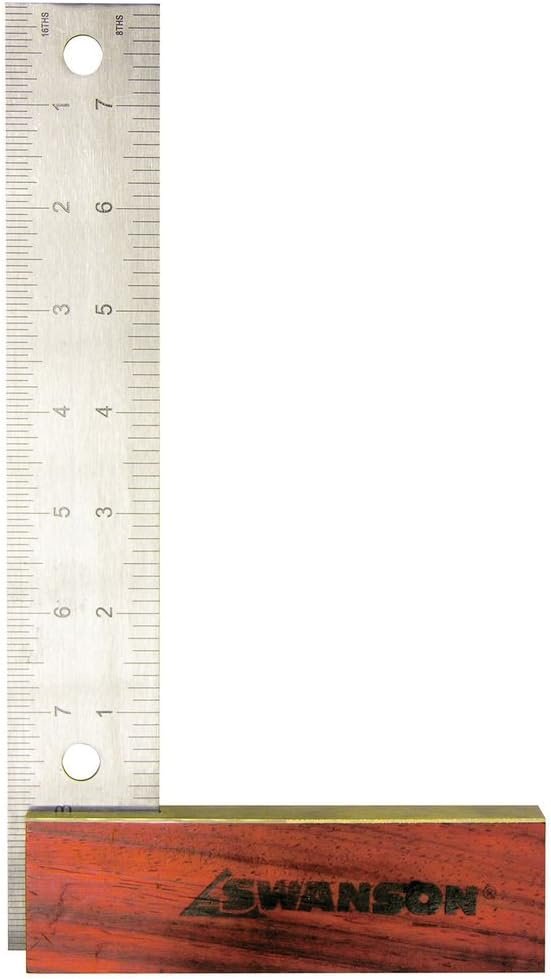

The material and construction of a try square are vital factors to consider. High quality try squares are typically made from durable materials like hardened steel or aluminum which ensure longevity and resistance to wear and tear. Wooden handles are also popular for their comfortable grip and traditional feel. Ensuring the blade and handle are securely joined and free of any play or movement is critical for maintaining accuracy over time. Investing in a well constructed try square will ensure it stands up to rigorous use in a workshop or on a job site.

Precision and Accuracy:

Accuracy is vital when selecting a try square. The tool’s blade must be perfectly perpendicular to the handle to ensure precise 90-degree measurements. Look for try squares that are machined to tight tolerances and come with certification of accuracy. Some high end models are individually tested and adjusted to ensure maximum precision. Choosing a try square with guaranteed accuracy will help avoid mistakes in your projects and ensure high quality results.

Blade Length and Versatility:

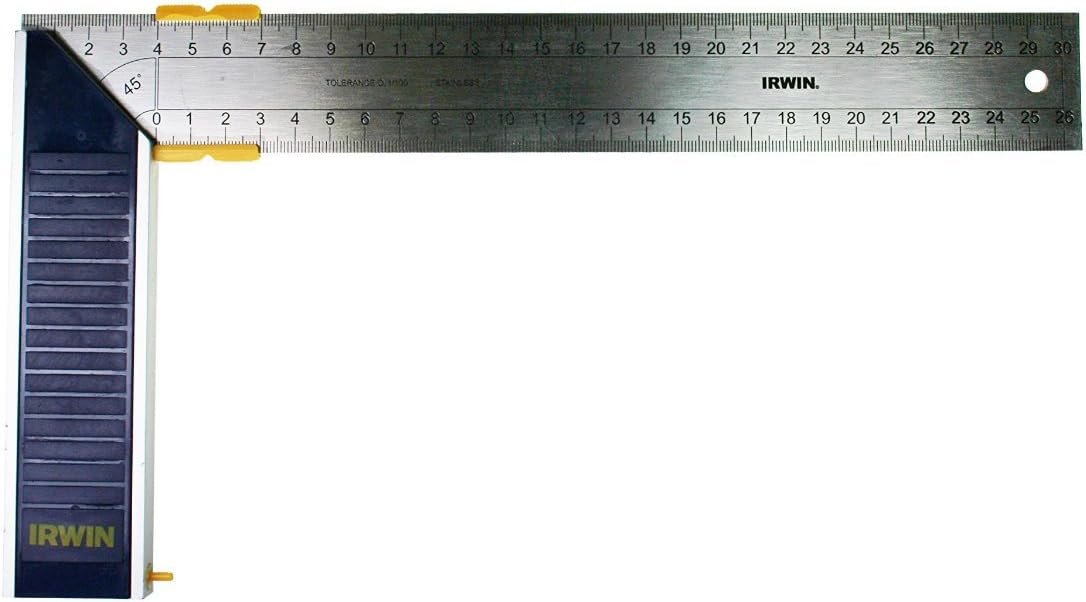

Try squares are available in various blade lengths typically ranging from 100mm (4”) to 300mm (12”) or more. The appropriate size depends on the scale of your projects. Smaller try squares are ideal for fine detailed work while larger ones are better suited for framing and large scale constructions. Some try squares feature graduated markings along the blade allowing them to double as rulers which can add versatility to your tool collection.

Handle Design and Ergonomics:

Comfort and ergonomics are important factors especially if you’ll be using the try square frequently. The handle should provide a comfortable grip and be easy to hold steady. Some try squares come with features like beveled edges or non-slip coatings that enhance grip and reduce hand fatigue. A well designed handle ensures the tool is easy to use and can improve the overall accuracy and efficiency of your work.

Brand Reputation and User Reviews:

The reputation of the brand and feedback from other users can provide valuable insights into the quality and reliability of a try square. Established brands with a track record of producing high quality tools are often a safe choice. Reading user reviews can reveal how the try square performs in real world conditions highlighting any potential issues or advantages. Reviews can also provide information on durability, accuracy and overall user satisfaction helping you make a well informed decision.

Budget and Value:

While budget is an important consideration it’s essential to balance cost with quality. High quality try squares might come with a higher price tag but they offer better durability and accuracy making them a worthwhile investment. Evaluate the features and construction quality within your budget range to ensure you get the best value. Sometimes spending a bit more upfront on a premium tool can save money in the long run by reducing the need for replacements and ensuring better project outcomes.

Warranty and Support:

A solid warranty and reliable customer support are important factors to consider when purchasing a try square. A good warranty offers peace of mind covering defects and ensuring that any issues can be resolved promptly. Brands that provide strong warranties and responsive customer support demonstrate confidence in their products and a commitment to customer satisfaction. Choosing a try square with a comprehensive warranty can provide added security and assurance.

Innovations and Additional Features:

Some try squares come with additional features that enhance their functionality. These might include laser etched measurements for better visibility built in bubble levels for checking plumb or adjustable blades for custom angles. While not necessary for all users these innovations can add convenience and versatility to your toolset. Consider whether any additional features would benefit your specific tasks and improve your efficiency.