Clicking on Amazon Services LLC Associates Program links on our site may earn us a commission. We provide unbiased overview of products and your support keeps us honest and objective. Thank you for helping us continue our work. Learn More →

Best Welders

top picks

Ranking

What’s in the Toolbox

tool

Good Points

tool overVIEW

WELDPRO (MIG200GDSV) BEST MIG/TIG/MMA Welder OVERALL

The WELDPRO MIG/TIG/MMA Welder (MIG200GDSV) is a highly versatile inverter welder designed for efficiency and performance across multiple welding processes including MIG, flux-cored arc welding (FCAW), DC Stick and Lift Arc TIG. Leveraging advanced IGBT inverter technology this compact welder delivers robust power in a lightweight package making it ideal for both home use and professional applications. The dual voltage capability allows for operation at 120 Volts or 240 Volts providing flexibility in various settings and enabling use with clean power generators which is particularly beneficial for outdoor projects.

Operating on 240 Volts, the WELDPRO (MIG200GDSV) offers impressive amperage ranges of 40 Amps – 200 Amps for MIG and Stick welding and 15 Amps – 200 Amps for TIG welding while maintaining a 30% duty cycle at maximum output. The synergic MIG control simplifies the setup process, allowing users to easily adjust settings for optimal welding conditions. The machine features a convenient setup for aluminum welding using the optional Weldpro SB8 spool gun. Safety is enhanced with Stick arc force adjustment and the availability of a voltage reduction device (VRD). Additionally, the WELDPRO (MIG200GDSV) is backed by a three-year power source warranty instilling confidence in its reliability and performance

features

WELDPRO (MIG200GDSV) BEST MIG/TIG/MMA Welder OVERALL

tool overVIEW

YESWELDER (MIG-250PRO) Best MIG/TIG/MMA Welder RUNNER UP

The YESWELDER MIG/TIG/MMA Welder (MIG-250PRO) is a 6-in-1 multi-process welder that offers a range of capabilities including MIG, Pulsed MIG, Flux Core, Spool Gun MIG, Lift TIG and Stick welding. This machine stands out due to its dynamic arc control which lets the user tailor the arc to either a crisp or soft setting based on their preferences and specific applications. For those looking to expand its functions, the TIG torch (WP-17V-35) and Spool Gun (LBT150) can be purchased separately enhancing its adaptability for various tasks.

Equipped with an advanced digital display, the YESWELDER (MIG-250PRO) provides clear and precise monitoring making the user experience smooth and efficient. The synergic MIG mode simplifies the welding process especially for beginners as it automatically adjusts the wire feed speed and recommended voltage. Professionals can take advantage of manual MIG settings for customized performance. The IGBT inverter technology incorporated in the YESWELDER (MIG-250PRO) ensures a powerful 250 Amp maximum output offering stable and reliable welding performance.

This welder supports different wire types making it suitable for diverse projects including aluminum welding via a spool gun. Safety features like automatic over-current, over-voltage and over-heating protection ensure that the unit is both energy-efficient and durable, promoting a safer and longer-lasting operation.

features

YESWELDER (MIG-250PRO) Best MIG/TIG/MMA Welder RUNNER UP

tool overVIEW

YESWELDER (MIG-205DS) Best MIG/TIG/MMA Welder ON A BUDGET

The YESWELDER MIG/TIG/MMA Welder (MIG-205DS) is a versatile 5-in-1 welding machine engineered for a range of welding applications, including Gas MIG, Flux Core MIG, Spool Gun MIG, Lift TIG and Stick welding. For TIG welding capabilities a separate lift TIG torch is required offering flexibility in various tasks. This model integrates an advanced digital display providing clear and precise feedback that enhances operational efficiency and allows for quick monitoring of adjustments and outputs.

Powered by IGBT inverter technology, the YESWELDER (MIG-205DS) delivers a full 30 Amp – 205 Amp range ensuring stable performance and reliable results. The synergic control feature simplifies the welding process by automatically adjusting voltage and wire feed speed based on selected amperage and material thickness making it suitable for both novice and experienced welders. Aluminum MIG welding is supported with spool gun compatibility with the LBT150 Spool Gun (sold separately) reducing wire travel distance and improving feed reliability.

The welder prioritizes safety with built-in automatic protection against over-current, over-voltage and overheating which extends the machine’s lifespan and promotes user safety. This blend of multi-functionality, user-friendly controls and advanced safety features make the YESWELDER (MIG-205DS) an excellent choice for diverse welding needs whether in home workshops or light professional settings.

features

YESWELDER (MIG-205DS) Best MIG/TIG/MMA Welder ON A BUDGET

tool overVIEW

LINCOLN ELECTRIC (K4876-1) Best MIG/TIG/MMA Welder AS AN ALTERNATIVE

The LINCOLN ELECTRIC MIG/TIG/MMA Welder (K4876-1) is a versatile and robust multi-process welder designed for general fabricators, small contractors and repair personnel. This machine excels in a range of welding applications offering the capability to perform MIG, Flux-Cored, Stick and DC TIG welding with consistent results. Its dual input voltage compatibility (120 Volts and 230 Volts) ensures that users can plug into almost any standard power supply enhancing its adaptability for different job sites.

The POWER MIG 215 MPi features an ergonomic and durable case with multiple lift points making it easy to transport and maneuver around the workshop. This portability combined with its lightweight 20.2 kgs (48 lbs.) design provides maximum mobility without sacrificing build quality. The integrated TIG solenoid and foot pedal adapter streamline the TIG welding setup allowing users to begin welding without complex installation steps. A reliable wire drive system ensures smooth and consistent wire feeding enhancing the welding experience and minimizing disruptions.

Innovative technology like Ready.Set.Weld simplifies setup by recommending optimal parameters for various processes, while ArcFX Technology offers instant visual feedback on setting adjustments helping welders refine their technique. Memory capability allows users to save and quickly recall welding settings improving efficiency for repeated tasks.

features

LINCOLN ELECTRIC (K4876-1) Best MIG/TIG/MMA Welder AS AN ALTERNATIVE

BEST Welders

tool Specification comparison table

Power Source

Corded Electric

Corded Electric

Corded Electric

Corded Electric

Input Voltage

115/230 Volts

220 Volts

110/220 Volts

120/230 Volts

Output Current

MIG: 40 Amps – 120 Amps (115 Volts)

40 Amps – 200 Amps (230 Volts)

TIG: 15 Amps – 120 Amps (115 Volts)

15 Amps – 200 Amps (230 Volts)

MMA: 40 Amps – 120 Amps (115 Volts)

40 Amps – 200 Amps (230 Volts)

MIG: 30 Amps – 250 Amps (220 Volts)

TIG: 10 Amps – 250 Amps (220 Volts)

MMA: 20 Amps – 250 Amps (220 Volts)

MIG: 30 Amps – 160 Amps (110 Volts)

30 Amps – 205 Amps (220 Volts)

TIG: 20 Amps – 160 Amps (110 Volts)

20 Amps – 205 Amps (220 Volts)

MMA: 30 Amps – 145 Amps (110 Volts)

20 Amps – 180 Amps (220 Volts)

MIG: 20 Amps – 220 Amps

TIG: 10 Amps – 175 Amps

MMA: 20 Amps – 175 Amps

Duty Cycle

MIG: 30% @ 120 Amps, 100% @ 66 Amps (115 Volts)

30% @ 200 Amps, 100% @ 110 Amps (230 Volts)

TIG: 30% @ 120 Amps, 100% @ 66 Amps (115 Volts)

30% @ 200 Amps, 100% @ 110 Amps (230 Volts)

MIG: 60% @ 250 Amps, 100% @ 193 Amps (220 Volts)

TIG: 60% @ 250 Amps, 100% @ 193 Amps (220 Volts)

MMA: 60% @ 225 Amps, 100% @ 174 Amps (220 Volts)

MIG: 60% @ 160 Amps, 100% @ 123 Amps (110 Volts)

60% @ 200 Amps, 100% @ 154 Amps (220 Volts)

TIG: 60% @ 160 Amps, 100% @ 123 Amps (110 Volts)

60% @ 205 Amps, 100% @ 158 Amps (220 Volts)

MMA: 60% @ 140 Amps, 100% @ 108 Amps (110 Volts)

60% @ 180 Amps, 100% @ 139 Amps (220 Volts)

MIG: 40% @ 105 Amps, 100% @ 80 Amps (120 Volts)

30% @ 215 Amps, 100% @ 120 Amps (230 Volts)

TIG: 40% @ 130 Amps, 100% @ 100 Amps (120 Volts)

30% @ 175 Amps, 100% @ 110 Amps (230 Volts)

MMA: 40% @ 85 Amps, 100% @ 60 Amps (120 Volts)

30% @ 175 Amps, 100% @ 110 Amps (230 Volts)

Included Components

(1) WELDPRO MIG/TIG/MMA Welder

(1) MIG gun NT1 180A 3m (10 ft.)

(1) TIG torch 17V 3.7m (12 ft.)

(1) Electrode holder 200A with 3m (10 ft.) cable and 35-50 Dinse connector

(1) Ground clamp 200A with 3m (10 ft.) cable and 35-50 Dinse connector

(1) Power adapter 115/230V

(1) Flow meter

(1) Gas hose

(1) 0.6mm (0.024”) – 0.9mm (0.035”) V-groove drive roller (solid wire)

(1) 0.8mm (0.030”) – 0.9mm (0.035”) K-groove drive roller (flux core wire)

(1) YESWELDER MIG-250 Pro MIG/TIG/MMA Welder

(1) 3m (10 ft.) MIG Gun (with a Graphene liner)

(1) Additional Teflon liner for aluminum wire

(1) 3m (10 ft.) MMA Electrode holder with cable

(1) 3m (10 ft.) ground clamp with cable

(1) Additional 0.8mm (0.030”) – 0.9mm (0.035”) contact tip

(1) W-type 0.8mm (0.030”) – 0.9mm (0.035”) roller driver

(1) V-type 0.6mm (0.023”) – 0.8mm (0.030”) roller driver 0.8mm (0.030”) – 0.9mm (0.035”) built-in

(1) U-type 0.9mm (0.035”) – 1.1 mm (0.045”) roll driver

(1) Dinse connector (35-50)

(1) Gas hose

(1) Brush

(1) User manual

(1) YESWELDER MIG-205DS Pro MIG/TIG/MMA Welder

(1) Graphene tube

(1) Ground Clamp

(1) Electrode Holder

(1) Driver Roll

(1) Adapter (Applicable to some countries)

(1) MIG Gun

(1) Gas Hose

(1) User Manual

(1) LINCOLN ELECTRIC MIG/TIG/MMA Welder

(1) K4076-1 Magnum PRO 175L Gun 3.0m (10 ft.)

(1) 230V to 120V Power Cord Adapter

(1) Work Cable and Clamp

(1) Electrode Holder and Lead Assembly

(1) Adjustable Gas Regulator and Hose

(1) Gasless Nozzle

(1) Gun Cable Liner (pre-installed in gun)

(1) Spindle Adapter

(1) ED030631 Sample 0.91 kgs (2 lbs.) Spool of SuperArc L-56 MIG Wire

(2) Contact Tips 0.6mm (0.025”)

(2) Contact Tips 0.9mm (0.035”)

(1) Drive Rolls in 0.6mm – 0.8mm (0.025” – 0.030”) and 0.9mm (0.035”) (Installed)

(1) Knurled Drive Roll 0.8mm -1.1mm (0.030” – 0.045”)

(1) Wire Guide 1.1 mm (0.045”) and 0.6mm – 0.9mm (0.025” – 0.035”) (Installed)

Wire Feed Speed (IPM)

Adjustable (specific range not provided)

80 – 500 IPM

Adjustable (specific range not provided)

50 – 500 IPM

Wire Diameter

Solid Wire: 0.6mm (0.023″), 0.8 mm (0.030″), 0.9mm (0.035″) and 1.0mm (0.040″)

Flux-Cored Wire: 0.8mm (0.030″), 0.9mm (0.035″) and 1.2mm (0.045″)

Solid Wire: 0.6mm (0.023″), 0.8 mm (0.030″), 0.9mm (0.035″) and 1.2mm (0.045″)

Flux-Cored Wire: 0.6mm (0.023″), 0.8mm (0.030″), 0.9mm (0.035″) and 1.2mm (0.045″)

Aluminum Wire: 0.6mm (0.023″), 0.8mm (0.030″), 0.9mm (0.035″) and 1.2mm (0.045″)

MMA: 7018/6011/6010 / 6013 electrode from 1.6 – 4.0mm (1/16″ – 5/32″)

Solid Wire: 0.6mm (0.023″) – 0.9mm (0.035″)

Flux-Cored Wire: 0.9mm (0.035″)

Aluminum Wire: 0.9mm (0.035″) and 1.2mm (0.045″)

MMA: 7018/6011 electrodes up to

3.0mm (1/8″) @ 110 Volts

4.0mm (5/32″) @ 220 Volts

Solid Wire: 0.6mm (0.025”) – 0.9mm (0.035”)

Flux-Cored Wire: 0.8mm (0.030”) – 1.2mm (0.045″)

MMA: 2.38mm (3/32”), 3.18mm (1/8”), 3.97mm (5/32”)

Gas and Gasless Capability

Gas-Shielded and Flux-Cored Welding

Gas-Shielded and Flux-Cored Welding

Gas-Shielded and Flux-Cored Welding

Gas-Shielded and Flux-Cored Welding

Compatible Materials

Mild Steel / Stainless Steel

Mild Steel / Aluminum / Stainless Steel

Mild Steel / Aluminum / Stainless Steel

Mild Steel / Aluminum / Stainless Steel

Weight

14 kgs (30.9 lbs.)

9.3 kgs (20.5 lbs.)

10.4 kgs (22.9 lbs.)

20.2 kgs (48 lbs.)

Warranty Description

3 Year Limited Warranty

1 Year Limited Warranty

1 Year Limited Warranty

3 Year Limited Warranty

Item Model Number

MIG200GDSV

MIG-250 PRO

MIG-205DS

K4876-1

Welders

0ther ALTERNATIves

what’s in the toolbox

tool

Key points

included components

Input Voltage: 230 Volts

Output Current: MIG 35 Amps – 190 Amps (230 Volts)

Duty Cycle: 15% @ 140 Amps (120 Volts)

25% @ 120 Amps (120 Volts)

60% @ 80 Amps (120 Volts)

100% @ 60 Amps (120 Volts)

Wire Diameter: 0.6mm (0.024”) – 0.9mm (0.035”)

Weight: 11.25 kgs (24.8 lbs.)

Warranty Description: 5/3/1 Year Limited Warranty

Item Model No.: 318

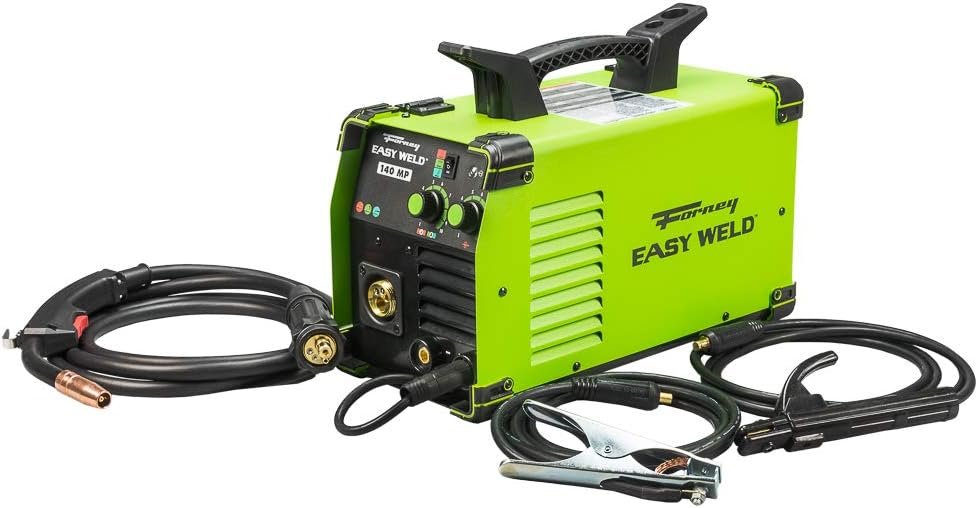

(1) FORNEY EASY WELD MIG/TIG/MMA Welder

(1) MIG gun with 3m (10 ft.) lead

(1) 3m (10 ft.) ground cable & clamp

(1) 4.5m (15 ft.) input power cable

(1) Gas hose and regulator

Input Voltage: 110/220 Volts

Output Current: MIG 40 Amps – 120 Amps (110 Volts)

40 Amps – 160 Amps (220 Volts)

TIG 20 Amps – 120 Amps (110 Volts)

20 Amps – 160 Amps (220 Volts)

MMA 0 Amps – 120 Amps (110 Volts)

20 Amps – 160 Amps (220 Volts)

Duty Cycle: MIG/TIG/MMA 60% @ 120 Amps, 100% @ 93 Amps (110 Volts)

60% @ 160 Amps, 100% @ 124 Amps (220 Volts)

Wire Diameter: Solid Wire 0.8mm (0.030”) – 0.9mm (0.035”)

Flux-Cored Wire 0.8mm (0.030”) – 0.9mm (0.035”)

Weight: 11.5 kgs (25.4 lbs.)

Warranty Description: 3 Year Limited Warranty

Item Model No.: YWM-160

(1) YESWELDER MIG/TIG/MMA Welder

(1) Work Clamp

(1) Electrode Holder

(1) Contact Tips (2 pieces)

(1) V Knurl Groove Drive Roller: 0.8mm (0.030”) – 0.9mm (0.035”) (on the machine)

(1) W Knurl Groove Drive Roller: 0.8mm (0.030”) – 0.9mm (0.035”)

(1) Gas Hose

(1) 220v-110V Power Plug

(1) MIG GUN

(1) Operator’s Manual

Input Voltage: 110 Volts

Output Current: MIG 35 Amps – 135 Amps

TIG 20A – 135 Amps

MMA 15 Amps – 135 Amps

Duty Cycle: MIG 60% @ 135 Amps, 100% @ 104 Amps

TIG 60% @ 135 Amps, 100% @ 104 Amps

MMA 60% @ 135 Amps, 100% @ 104 Amps

Wire Diameter: Flux-Cored Wire 0.8mm (0.030”) – 0.9mm (0.035”)

Weight: 5.04 kgs (11.13 lbs.)

Warranty Description: 1 Year Limited Warranty

Item Model No.: FLUX-135PRO

(1) YESWELDER Flux MIG/TIG/MMA Welder

(1) MIG Gun

(1) 2m (6.5 ft.) Earth Clamp & Cable

(1) 2m (6.5 ft.) Electrode Holder & Cable

(1) Contact Tips 0.8mm (0.030”) & 0.90mm (0.035”)

(1) Manual

Input Voltage: 120/230 Volts

Output Current: MIG 20 Amps – 211 Amps (120 Volts)

20 Amps – 211 Amps (230 Volts)

Duty Cycle: MIG 60% @ 95 Amps, 100% @ 75 Amps (120 Volts)

30% @ 175 Amps, 100% @ 90 Amps (230 Volts)

Wire Diameter: Solid Wire 0.6mm (0.025”) – 0.9mm (0.035”)

Flux-Cored Wire 0.8mm (0.030”) – 1.2mm (0.045”)

Weight: 18.6 kgs (41 lbs.)

Warranty Description: 3 Year Limited Warranty

Item Model No.: K6080-1

(1) LINCOLN ELECTRIC MIG Welder

(1) Magnum Pro 100L gun

(1) Work cable with clamp

(1) Spare contact tips

(1) Gas regulator and gas hose

(1) Gas nozzle

(1) 120V to 230V Input Adapter

(1) Sample spool of MIG wire

(1) Spindle adapter

(1) Quick setup guide and literature

Input Voltage: 110/115/120 Volts

Output Current: MIG 25 Amps – 140 Amps

Duty Cycle: MIG 20% @ 90 Amps

Wire Diameter: Solid Wire 0.6mm (0.023”) – 0.9mm (0.035”)

Flux-Cored Wire 0.8mm (0.030”) – 0.9mm (0.035”)

Aluminum Wire 0.8mm (0.030”)

Weight: 25.8 kgs (57 lbs.)

Warranty Description: 5 Year Limited Warranty

Item Model No.: 500559

(1) HOBART MIG Welder

(1) Comfortable 3m (10 ft.) HR-100 gun

(1) Comfortable 3m (10 ft.) HR-100 gun

(1) Owner’s manual with installation, operation and maintenance guidelines.

(1) 3m (10 ft.) work cable with clamp

(1) Built-in gas solenoid valve and dual-gauge regulator with gas hose

(1) Spool hub assembly accommodates 101.6mm (4”) or 203.2mm (8”) spools

(1) Sample spool of 0.8mm (0.030”) self-shielding flux-cored wire

(1) 0.8mm (0,030”) contact tips

(1) Quick Select™ drive roll for 0.6mm (0.024) or 0.8mm/0.9mm (0.030”/0.035”) solid wire and 0.8mm/0.9 mm (0.030”/0.035”) flux-cored wire

(1) Power cord with plug

Welding guide and material thickness gauge

Input Voltage: 120 Volts

Output Current: MIG 10 Amps – 140 Amps (120 Volts)

Duty Cycle: MIG 30% @ 90 Amps (120 Volts)

TIG 30% @ 110 Amps (120 Volts)

MMA 30% @ 80 Amps (120 Volts)

Wire Diameter: Solid Wire 0.8mm (0.030”) – 0.9mm (0.035”)

Flux-Cored Wire 0.8mm (0.030”) – 0.9mm (0.035”)

Weight: 11.25 kgs (24.8 lbs.)

Warranty Description: 1 Year Limited Warranty

Item Model No.: 271

(1) FORNEY EASY WELD MIG/TIG/MMA Welder

(1) 3m (10 ft.) MIG gun

(1) 2.4m (8 ft.) electrode holder

(1) 2.4m (8 ft.) ground clamp,

(1) 20 Amp – 15 Amp adaptor

(1) 0.8mm (0.030”) contact tip

Input Voltage: 110/220 Volts

Output Current: 10 Amps – 200 Amps

Duty Cycle: TIG 60% @ 200 Amps

MMA 40% @ 200 Amps

Wire Diameter: Not Applicable

Weight: 10.9 kgs (24 lbs.)

Warranty Description: 3 Year Limited Warranty

Item Model No.: opikll-530

(1) WELDPRO TIG/MMA Welder

(1) TIGACDC200GD welder

(1) CK17 superflex TIG torch

(1) TIG torch

(1) Trigger button for TIG torch

(1) Torch protection cover

(1) Weldpro foot pedal

(1) Electrode holder 3m (10 ft.) 200A 35-50 Dinse connector

(1) Ground clamp 3m (10 ft.) 300A 35-50 Dinse connector

(1) Flow meter

(1) Gas hose

(1) Power adapter 115/230V

(1) Consumables kit

Input Voltage: 120/230 Volts

Output Current: 10 Amps – 90 Amps (120V)

10 Amps – 180 Amps (230 Volts)

Duty Cycle: 30% @ 80 Amps (120 Volts)

25% @ 180 Amps (230 Volts)

Wire Diameter: Not Applicable

Weight: 4.38 kgs (9.65 lbs.)

Warranty Description: 1 Year Limited Warranty

Item Model No.: 291

(1) FORNEY EASY WELD TIG/MMA Welder

(1) Electrode holder and clamp

(1) Ground clamp and cable

(1) 230V to 120V adapter

(1) 1.8m (6 ft.) power cord

Input Voltage: 110/220 Volts

Output Current: 20 Amps – 140 Amps (110 Volts)

20 Amps – 160 Amps (220 Volts)

Duty Cycle: TIG 60% @ 160 Amps, 100% @ 124 Amps (110 Volts)

60% @ 200 Amps, 100% @ 155 Amps (220 Volts)

MMA 60% @ 140 Amps, 100% @ 108 Amps (110 Volts)

60% @ 160 Amps, 100% @ 124 Amps (220 Volts)

Wire Diameter: Not Applicable

Weight: 4.85kgs (10.71 lbs.)

Warranty Description: 1 Year Limited Warranty

Item Model No.: TIG-205P

(1) YESWELDER TIG/MMA Welder

(1) Ground clamp

(1) Electrode holder

(1) 220v to 1IOV adapter

(1) Argon gas hose

(1) Wp-17 tig torch

(1) Tig torch consumables

Input Voltage: 110/220 Volts

Output Current: 20 Amps – 145 Amps (110 Volts)

20 Amps – 205 Amps (220 Volts)

Duty Cycle: MMA 60% @ 145 Amps,

100% @ 112 Amps (110 Volts)

MMA 60% @ 205 Amps,

100% @ 158 Amps (220 Volts)

Wire Diameter: Not Applicable

Weight: 3.8 kgs (8.4 lbs.)

Warranty Description: 3 Year Limited Warranty

Item Model No.: ARC-205DS

(1) YESWELDER TIG/MMA Welder

(1) Stick welder

(1) Ground clamp

(1) Electrode holder

(1) 220V to 110V Adapter

a Tool for Every Job

Welding machines are fundamental for tradespeople and DIY enthusiasts who want to fabricate or repair metal structures with precision and efficiency. For professionals, the right welder can be an essential tool offering capabilities that handle various welding processes such as MIG, TIG, Stick and Flux-Cored. This multi-process versatility allows for seamless adaptation to different materials and tasks making projects more efficient and reducing the need for multiple machines. Advanced machines now feature lightweight portable designs with ergonomic builds perfect for both shop use and on-site work.

DIY enthusiasts can find accessible options that include intuitive controls, clear digital displays and preset settings that make operation easier. These user-friendly machines cater to hobbyists who wish to take on custom projects or home repairs without extensive training. Safety is an essential factor and modern welders come equipped with built-in protections like over-voltage and over-heating safeguards to ensure safe usage and long-lasting operation.

Dual-voltage capability is another key feature that adds flexibility enabling welders to work in varied locations with different power setups. As welding technology continues to evolve machines are now more efficient, durable and easier to use allowing both seasoned tradespeople and new DIYers to tackle projects with confidence and achieve quality results.

BUYERS GUIDE

Welders

Welding Machine Types:

When purchasing a welding machine, it’s essential to consider the type of welding processes you will be performing. The most common types are MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), Stick and Flux-Cored welding. MIG welders are often favored for their ease of use and speed making them suitable for beginners and professionals. On the other hand, TIG welders offer greater control and are ideal for thin materials and precision work. Stick welders are versatile and can be used outdoors while Flux-Cored welders are great for projects that require portability and minimal setup. Understanding these types will help you choose a machine that aligns with your specific needs.

Power Supply and Portability:

Another critical factor to consider is the power supply options available for the welding machine. Many welders come with dual voltage capabilities allowing them to operate on both 120V and 240V outlets. This feature enhances portability making it easier to use the welder in various locations whether in a shop or at a job site. If you plan to move your welder frequently consider its weight and design as well. Look for machines with ergonomic handles and wheels for easy transport. Ensuring that your welding machine can adapt to different power sources will maximize its usability.

Features and Technology:

Modern welding machines are equipped with advanced features that enhance their performance and ease of use. Look for machines with digital displays that provide real-time feedback on settings and welding parameters. Features such as synergic control which automatically adjusts voltage and wire feed speed based on the selected amperage can significantly benefit beginners by simplifying the setup process. Safety features, such as over-voltage and over-current protection are also essential for ensuring safe operation. The inclusion of these technologies not only improves efficiency but also helps in achieving consistent and high-quality welds.

Budget and Brand Reputation:

Your budget will play a significant role in your choice of a welding machine. While it’s tempting to consider the cheapest option, investing in a high-quality welder from a reputable brand can pay off in the long run. Look for machines with good warranties and customer support as these can be indicators of a brand’s reliability and commitment to quality. Research different brands and read reviews from other users to understand their experiences and the machine’s overall performance. By balancing your budget with quality and features you can find a welding machine that meets your needs and expectations.

Maintenance and Durability:

When selecting a welding machine, it’s crucial to consider the maintenance requirements and overall durability of the unit. High-quality welders are typically constructed from robust materials that can withstand regular use and harsh conditions. Look for machines with reliable wire drives and strong feed mechanisms as these components often determine the longevity and performance of the welder. Regular maintenance such as cleaning the machine and checking for wear and tear will also ensure optimal performance over time. Understanding the maintenance needs and durability of your chosen machine can help prevent unexpected breakdowns and costly repairs.

Accessories and Add-Ons:

When purchasing a welding machine consider the availability of accessories and add-ons that can enhance your welding capabilities. Many manufacturers offer compatible tools such as spool guns, TIG torches and protective gear that can significantly improve your welding experience. For instance, if you’re looking to perform aluminum welding investing in a spool gun compatible with your MIG welder can make a considerable difference in feed and quality. Additional accessories like welding helmets, gloves and protective clothing are also essential for ensuring safety during operation. Assessing the available accessories can help you maximize the functionality of your welder and ensure you’re fully equipped for various projects.

Training and User-Friendliness:

For both beginners and experienced welders, the user-friendliness of a welding machine can greatly influence the learning curve and overall experience. Look for machines that offer clear instructional manuals, online tutorials and accessible controls that simplify operation. Features such as automatic settings and guided adjustments can help new users quickly understand the machine’s functionality. If possible, consider testing the welder before purchasing to gauge how comfortable you feel with its controls. Investing in a welder that is easy to use can enhance your skills and confidence leading to better results in your projects.

Reviews and Community Feedback:

Before making a purchase, it’s beneficial to read reviews and seek feedback from the welding community. Online forums, social media groups and review sites provide valuable insights into the performance and reliability of specific welding machines. Engaging with other welders can help you discover potential issues, benefits and tips for using different models. Look for reputable sources that aggregate user reviews to get a well-rounded perspective on the product you’re considering. Understanding what real users have experienced can inform your decision and help you select a machine that meets your needs.

Warranty and Customer Support:

A strong warranty is a vital factor when purchasing a welding machine as it reflects the manufacturer’s confidence in their product. Many reputable brands offer warranties ranging from one year to several years, covering parts and labor. This safety net can save you money in case of defects or operational issues. Additionally, good customer support is essential for troubleshooting and obtaining replacement parts. Brands that provide comprehensive support such as online resources, customer service hotlines and local service centers can make a significant difference in your overall experience with the machine. Researching warranty terms and customer support options before purchasing can offer peace of mind.